A global designer and Manufacturer of EMS solution provider

Our vertically integrated Electronic Manufacturing Services (EMS) capabilities provide our customers with significant benefits when it comes to product manufacturing, assembly and supply.

-

-

What we do?

Rapid PrototypingContract designNew Product IntroductionPCB Assembly & TestCable & Harness assemblyManufacturingBox-Build AssemblyTest Development & ImplementationPlastic Injection MoldingPlastic Thermoforming

-

-

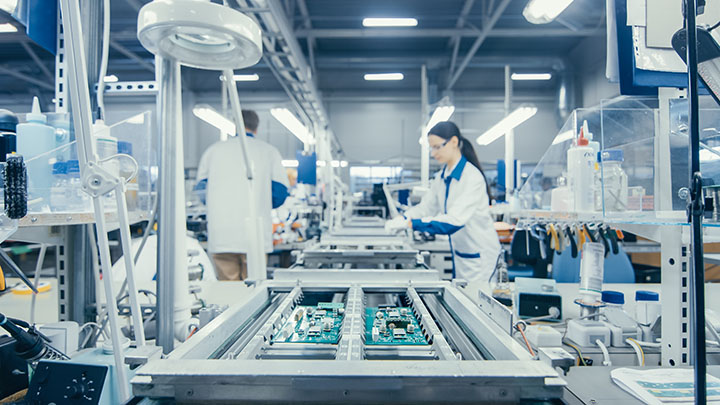

Eelectronic Manufacturing Service

Operating in several locations across China and Vietnam, PYS is a full-service, high-mix, low- to mid-volume EMS provider with a proven track record of delivering high-quality, custom-designed electronic manufacturing services and supply chain solutions to a diverse group of OEMs.

-

-

New Product Introduction (NPI)

Complete End-to-End NPI Services

DFM (design for manufacturability)

DFT (design for testability)

BOM review

Risk analysis

Lead-time analysis

Availability analysis

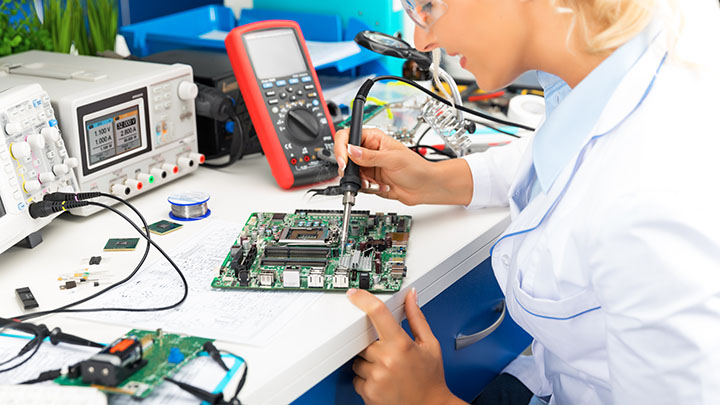

Test development and implementation

Test strategy/plan

Flying probe (FP)

In-circuit test (ICT)

Functional test

Boundary scan

Customer supplied equipment

PPAP (production part approval process)

PFMEA (process failure modes and effects analysis)

-

-

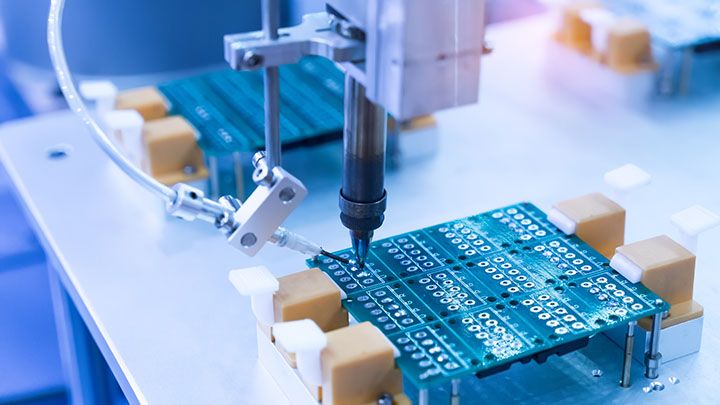

Printed Circuit Board Assembly (PCBA)

PCBA at the heart of our electronic contract manufacturing company

Our cutting-edge equipment and years of expertise allow us to be one of the most active printed circuit board assembly manufacturers, worldwide. Contract manufacturer delivering engineering and manufacturing services to all industries, we''ve started our history with printed circuit board assembly before offering fully integrated solutions, from design to mass production, to our customers.

-

-

Cable & Wire Harness Assembly

Our products associated with these services include:

Harsh-environment cable assemblies

Harnesses

Control panels/boxes

Mechanical subassemblies

Panel wiring and assembly

PYS provide engineering, testing, and manufacturing the products.

-

-

Advanced Engineering Services

Design for Excellence (DFX)

- Reduced lead time and material costs (DFSC)

- Improved PCB yield and cost (DFF)

- Improved assembly yield and reduced labor content (DFA)

- Improved coverage and final yield, reduced RMA, and field failures (DFT)

- Reduced engineering development and resources, improved time to market (development)

- Improved production stability and predictability (DFM)

- Continuous improvement (post-DFM, ROI).